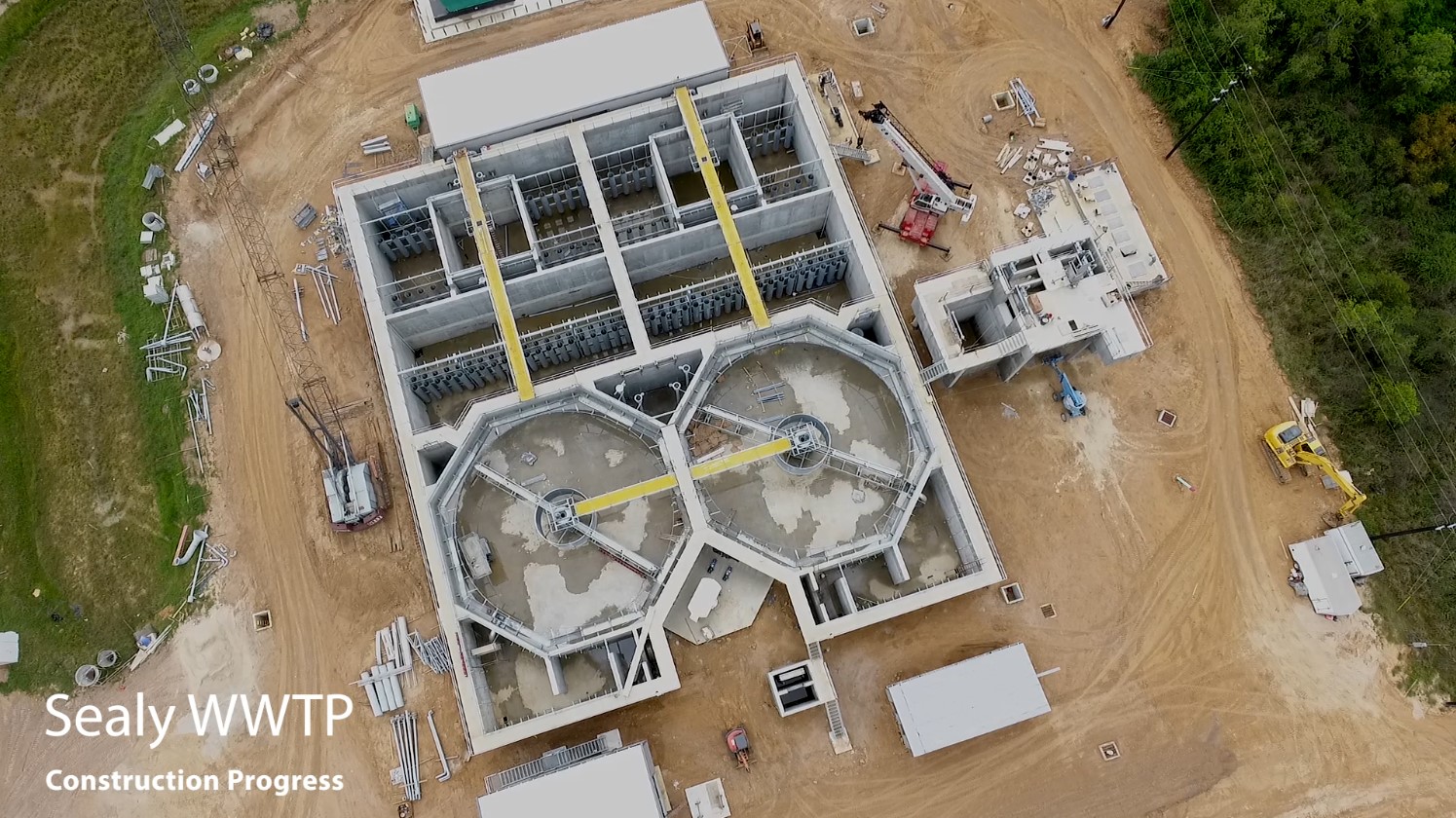

We provided the design of this 2.0 million gallon per day WWTP expansion in response to growth within the city. The expansion included assistance in the acquisition of neighboring property to enable construction of a new treatment facility without disturbing the existing site. Our design utilized common wall concrete tankage that reduced the amount of additional land required for the expansion. This common wall design also saved the City on costs for concrete tankage and yard piping.

The new WWTP includes a dual train activated sludge system with a new influent pumping station and headworks (with screening and grit removal), new high efficiency blowers, aerobic digestion, belt filter press dewatering, chlorine disinfection, and a new control building. The dual train design enables use of only half of the facility until flows and loadings require use of the second treatment train. One design and construction challenge for this project was routing of influent and effluent line piping in the same vicinity as active petroleum piping. We maintained the minimum required separation distances from the existing petroleum pipeline while still enabling proper sewage flow. We also addressed stormwater runoff for the project site and the neighboring areas.

Back to Project Gallery